How does the designing, tailoring and printing packaging boxes and bags process work in Madar Company?

Share

At Madar Company, the process of designing, tailoring, and printing packaging boxes and bags is a meticulous and highly coordinated endeavor, aimed at delivering top-notch products that meet the specific needs of our clients. It all starts with a deep understanding of the client's requirements. We engage in comprehensive consultations to gather detailed information about the product dimensions, target market, branding guidelines, and any special requests the client might have. This initial phase ensures that we have a clear vision of what the client wants to achieve with their packaging.

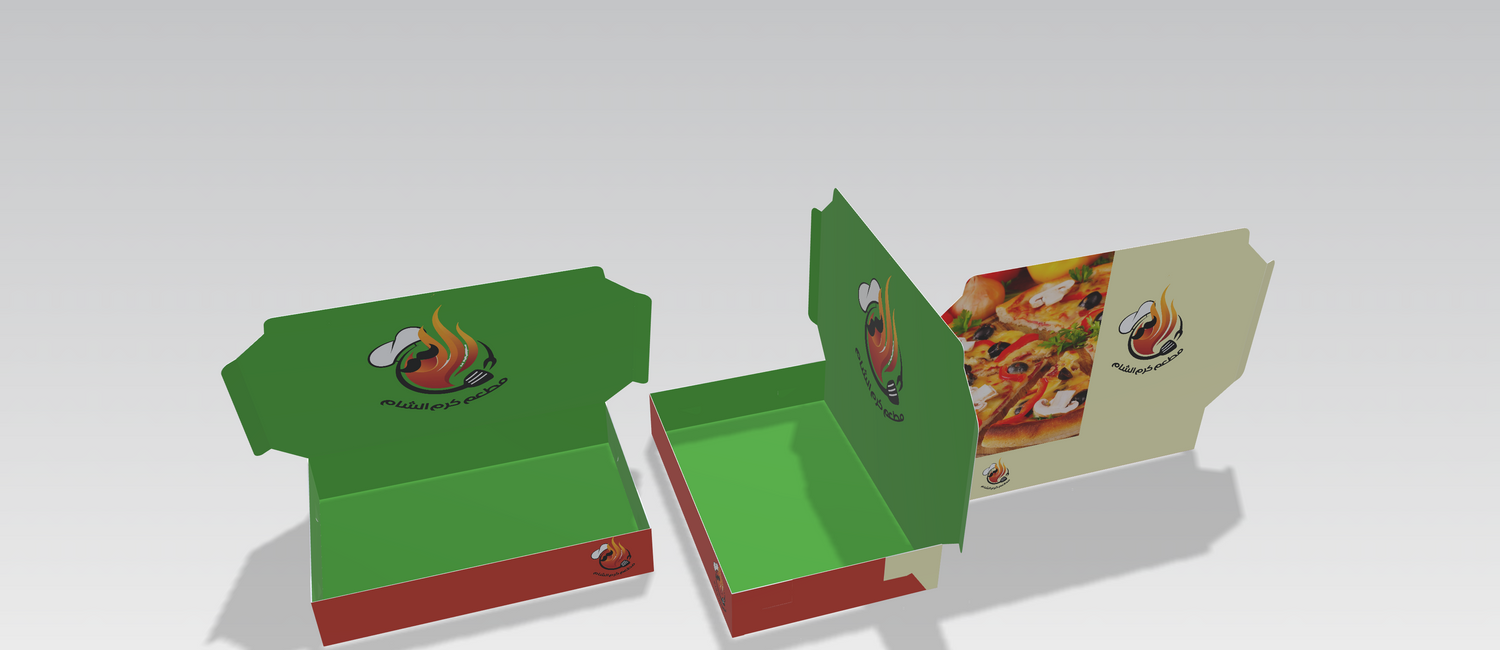

Once the requirements are crystal clear, our talented design team steps in. They leverage the latest design software to create visually appealing and functional packaging concepts. These designs are then presented to the client for feedback and approval. We believe in a collaborative approach, so we work closely with the client to tweak and refine the designs until they are perfectly aligned with their brand identity and marketing goals.

After the design phase, we move on to the tailoring and printing stages. Our state-of-the-art production facilities are equipped with advanced machinery that can handle a wide range of materials and printing techniques. Throughout the production process, we adhere to strict quality control measures to ensure that every box and bag is crafted to perfection. From cutting and folding to printing and finishing, every step is executed with precision. Finally, the finished products are carefully inspected, packed, and delivered to the client, ready to enhance the presentation and protection of their products.

In essence, at Madar Company, we pride ourselves on our ability to transform ideas into tangible, high-quality packaging solutions that help our clients stand out in the market.

Once the requirements are crystal clear, our talented design team steps in. They leverage the latest design software to create visually appealing and functional packaging concepts. These designs are then presented to the client for feedback and approval. We believe in a collaborative approach, so we work closely with the client to tweak and refine the designs until they are perfectly aligned with their brand identity and marketing goals.

After the design phase, we move on to the tailoring and printing stages. Our state-of-the-art production facilities are equipped with advanced machinery that can handle a wide range of materials and printing techniques. Throughout the production process, we adhere to strict quality control measures to ensure that every box and bag is crafted to perfection. From cutting and folding to printing and finishing, every step is executed with precision. Finally, the finished products are carefully inspected, packed, and delivered to the client, ready to enhance the presentation and protection of their products.

In essence, at Madar Company, we pride ourselves on our ability to transform ideas into tangible, high-quality packaging solutions that help our clients stand out in the market.